| Name: | Honeycomb activated carbon /High efficiency adsorption rate |

|---|---|

Product Description

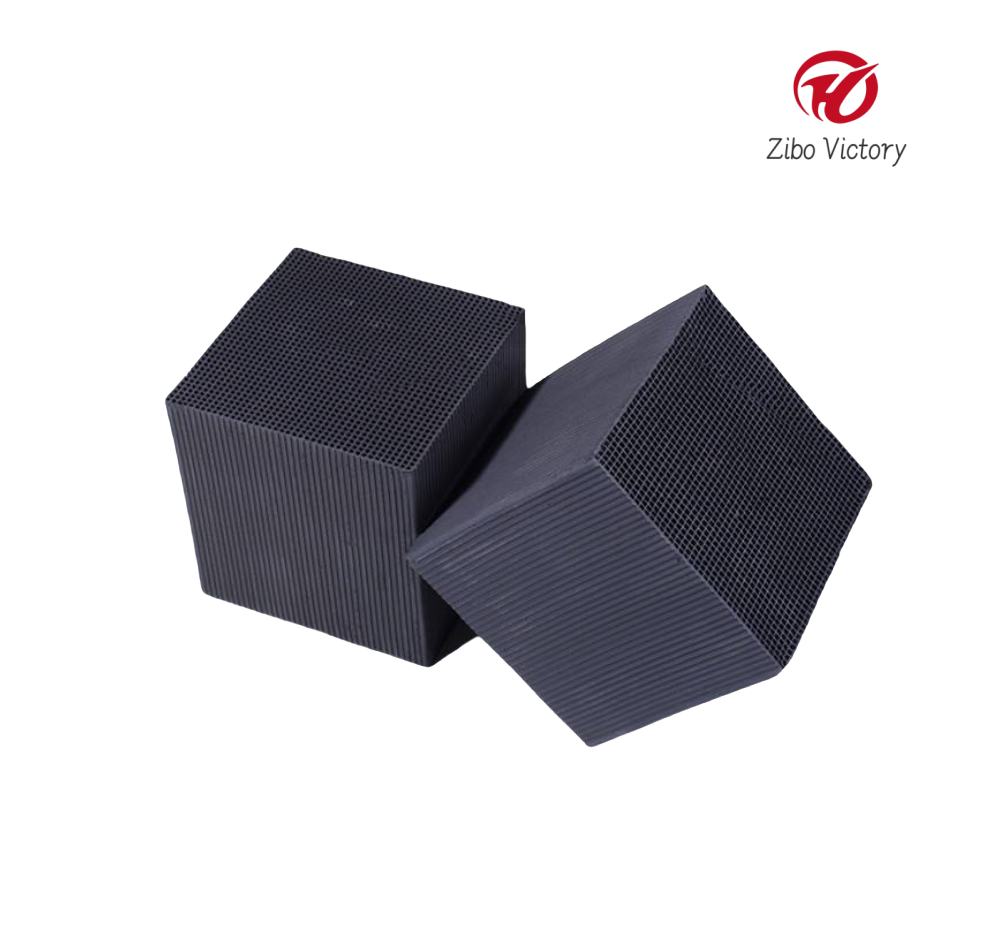

Honeycomb activated carbon is the use of high-quality raw coal as a raw material to extrude molding, activated by high temperature, the market is very little useful wood as a raw material to use.

The production principle is that raw materials and coal tar, asphalt or other adhesives in accordance with a certain proportion of blending, extrusion molding, according to the size of the grinding tool, can be processed into 100mm*100mm*100mm cuboid or 50mm*50mm*100mm cuboid to make, and then through 800C° high temperature activation.

Honeycomb activated carbon is widely used, mainly used in air treatment, VOC treatment, etc., due to its unique square aperture, so that it is extremely good air mobility in the equipment, and, in the air (waste gas) through the honeycomb carbon layer, only through the square hole of honeycomb activated carbon, the electrostatic attraction of activated carbon will quickly capture all the molecules suitable for its own aperture, So as to achieve the purpose of purification.

Technical parameters of honeycomb activated carbon

Specification |

50mm, 100mm |

Benzene adsorption value |

20-40 |

Iodine adsorption value |

500-800mg/g |

Desorption temperature |

110C° |

Specific surface area |

500-900m²/g |

Empty tower wind speed |

0.8m/s |

CTC(Carbon tetrachloride) |

30-40% |

Static adsorption rate |

30-50% |

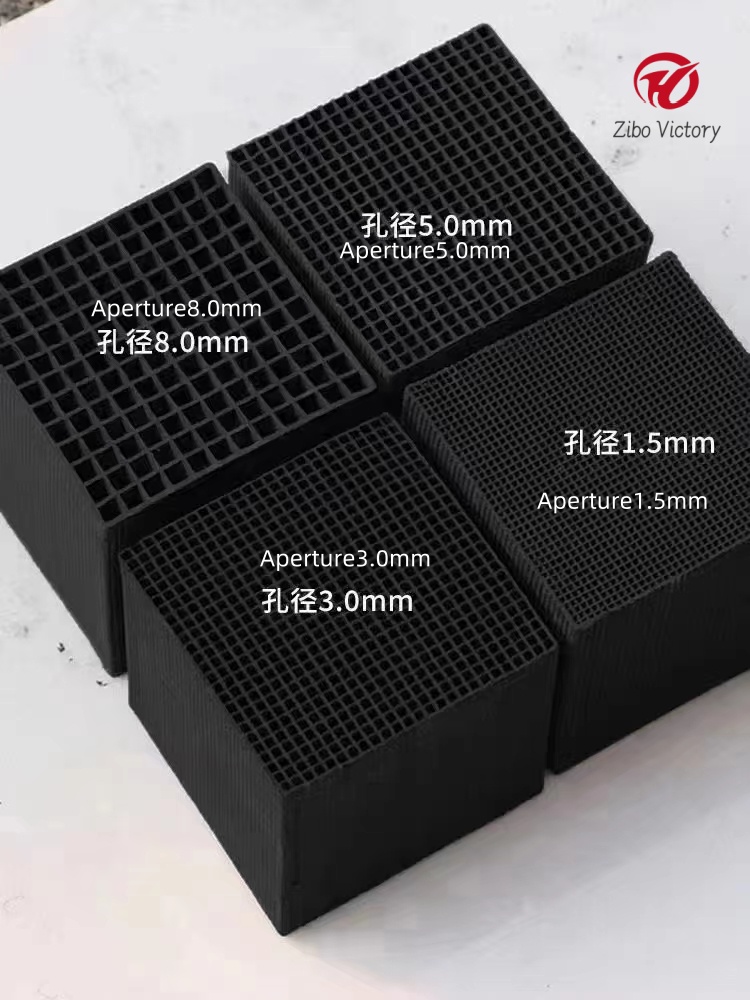

Aperture |

1.5mm |

Positive compressive strength |

1mpa |

Bulk density |

0.4-0.6g/cm³ |

Lateral compressive strength |

0.7mpa |

Moisture |

≤5 |

Wall thickness |

1mm |

Honeycomb activated carbon is the use of high-quality raw coal as a raw material to extrude molding, activated by high temperature, the market is very little useful wood as a raw material to use.

Send Email

Send Email +8613325203316

+8613325203316