How is the modular oxygen generator used?

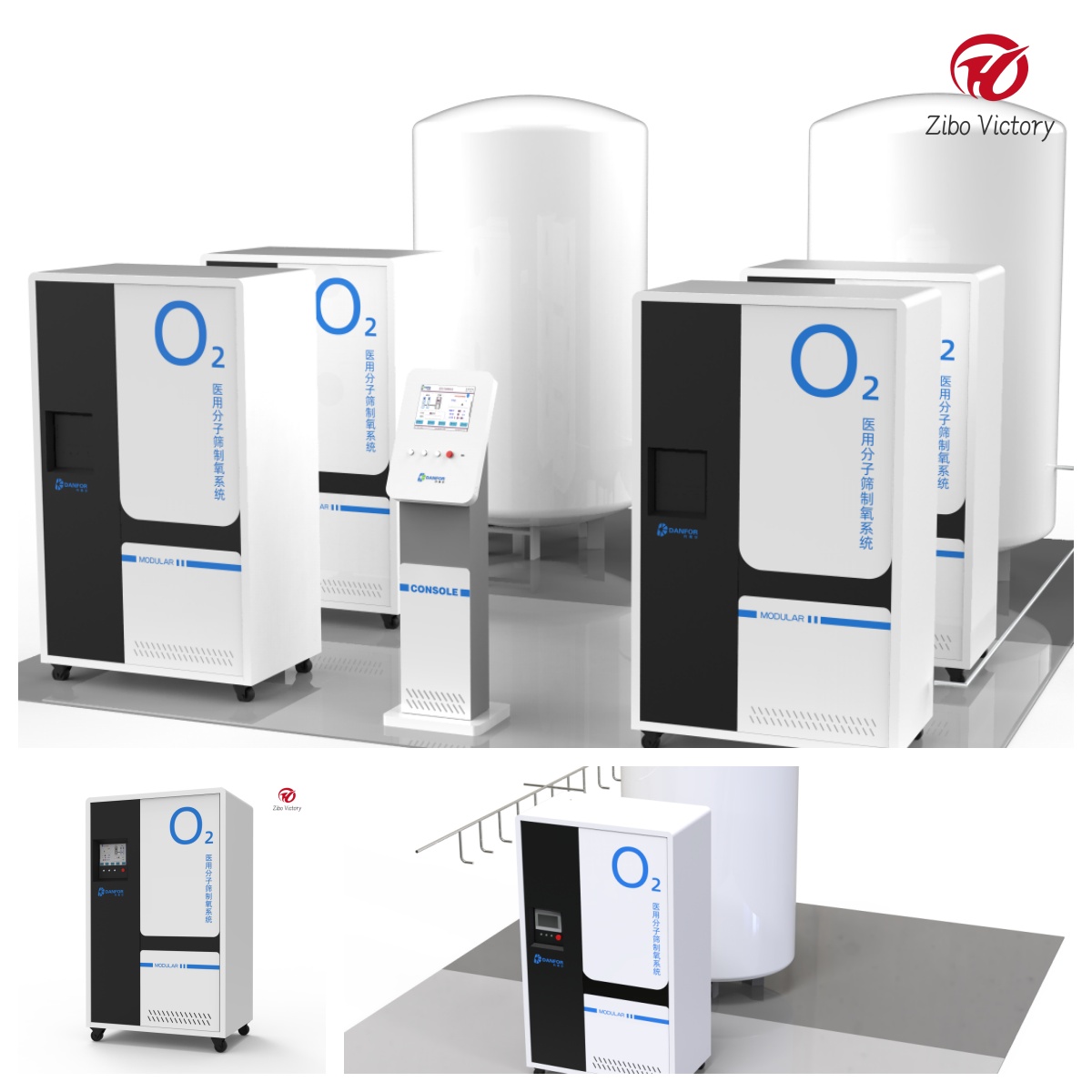

Modular Oxygen Generator

Introduction

A Modular Oxygen Generator is an advanced oxygen production system designed with scalable and flexible modules. It utilizes Pressure Swing Adsorption (PSA) or Membrane Separation Technology to extract oxygen from ambient air, offering a cost-effective and on-site oxygen supply solution.

Key Features

Modular Design: Units can be combined or expanded to meet varying oxygen demands (1–1000 Nm³/h).

High Efficiency: Energy-saving operation with oxygen purity adjustable between 90%–95% (medical grade) or industrial-grade (≥99%).

Compact & Portable: Suitable for remote areas, emergency scenarios, and mobile applications.

Applications

Healthcare

Centralized oxygen supply for hospitals, ICUs, and emergency medical services.

Mobile oxygen solutions for disaster relief.

Industry

Supports metal cutting, chemical synthesis, and wastewater treatment.

Enhances combustion efficiency in furnaces and boilers.

Environmental & Aquaculture

Oxygenation for sewage treatment and high-density fish farming.

High-Altitude Solutions

Provides stable oxygen supply in mountainous regions or mining sites.

Advantages

Customizable: Tailored configurations for specific capacity and purity requirements.

Low Maintenance: Automated controls and modular replacement reduce downtime.

Sustainable: Eliminates dependency on oxygen cylinders, lowering carbon footprint.

Send Email

Send Email +8613325203316

+8613325203316