What are the differences between modular medical oxygen generator and traditional oxygen generator?

http://zibovictroy.com/product-69.html

The differences between modular medical oxygen generators and traditional oxygen generators can be understood through their design, functionality, and application. Below is a structured comparison based on the provided search results:

1. Design and Configuration

Modular Systems:

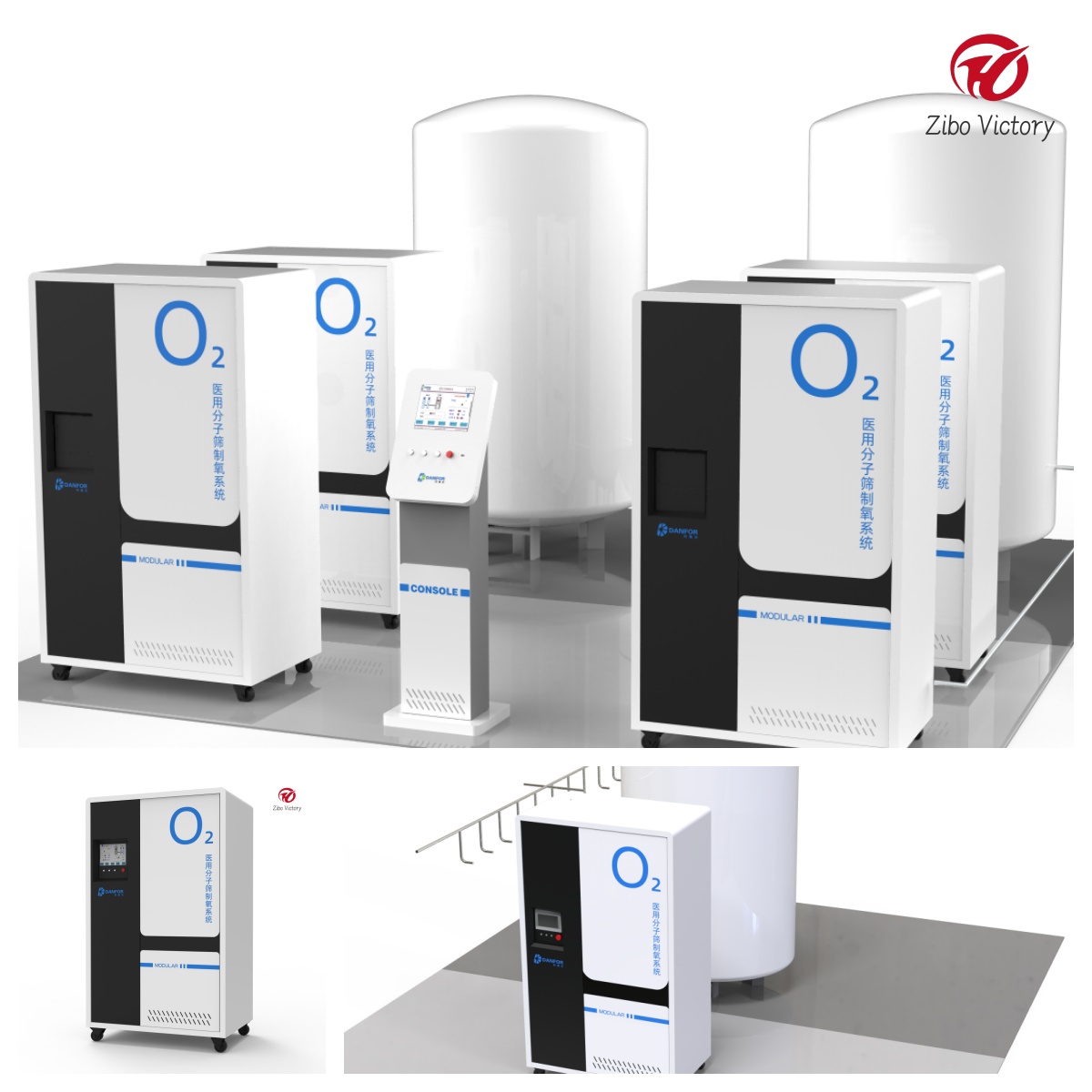

Integrated Components: Modular units combine components like air compressors, molecular sieve towers, and filtration systems into a single, scalable framework. For example, the ETR containerized oxygen generator integrates screw compressors, dryers, and control systems in a compact design 13.

Flexibility: They allow on-site customization and expansion by adding modules (e.g., additional adsorption towers or storage tanks) to meet varying oxygen demands 112.

Portability: Some models, like the Fusheng Mo-02, use "damping suspension systems" to reduce vibration and noise, making them suitable for mobile or temporary medical facilities 2.

Traditional Systems:

Fixed Structure: These are often single-unit systems with predefined configurations (e.g., BSZY series with fixed flow rates and pressures) 1.

Bulkier Setup: Components like liquid oxygen tanks or manifold systems require more space and permanent installation 3.

2. Oxygen Production and Efficiency

Modular Generators:

On-Demand Oxygen: Utilize PSA (Pressure Swing Adsorption) technology to produce oxygen directly from air, eliminating the need for stored oxygen. For instance, the PRO2XY VAC model generates oxygen at 95% purity on demand 12.

Energy Efficiency: Advanced designs like Fusheng’s oil-free scroll compressors reduce energy consumption by optimizing airflow and pressure cycles 2.

Traditional Generators:

Reliance on Storage: Often depend on liquid oxygen tanks or cylinders, which require regular refilling and pose logistical challenges 3.

Higher Energy Use: Older PSA models may lack energy recovery mechanisms, leading to higher power consumption 1.

3. Maintenance and Safety

Modular Systems:

Easier Maintenance: Accessible components (e.g., replaceable molecular sieves) and remote monitoring capabilities reduce downtime. The OXYBERG® 500-800 includes automated self-checks and error alerts 112.

Safety Features: Low-pressure oxygen supply (0.2–0.5 MPa) minimizes explosion risks, and integrated filters ensure medical-grade purity (93%±3%) 23.

Traditional Systems:

Complex Upkeep: Manifold systems with multiple cylinders or liquid oxygen tanks require manual inspections and pose flammability risks during storage 3.

4. Applications and Scalability

Modular Generators:

Versatility: Suitable for hospitals, clinics, and emergency settings due to their adaptability. The OGP series by Atlas Copco supports both low-flow (5 m³/h) and high-flow (200 m³/h) needs 112.

Scalability: Can be expanded by adding modules (e.g., increasing adsorption towers) to match growing demand 1.

Traditional Systems:

Limited Scalability: Fixed capacity makes them less ideal for dynamic healthcare environments. For example, liquid oxygen tanks have finite storage and require infrastructure for refills 3.

5. Cost and Installation

Modular Systems:

Lower Long-Term Costs: Eliminate recurring expenses for oxygen delivery and storage. The AmcareMed OY series highlights reduced operational costs through electricity-only consumption 1.

Simplified Installation: Pre-assembled units (e.g., skid-mounted or containerized designs) enable rapid deployment 112.

Traditional Systems:

Higher Operational Costs: Expenses include cylinder replacements, storage maintenance, and transportation

Send Email

Send Email +8613325203316

+8613325203316